SD

Eliminating the water from the sludge by evaporation reduces its volume and weight, making for easier storage, transportation & its further treatment.

Drying stabilizes the sludge, thereby reducing olfactory nuisances and improving sanitization.

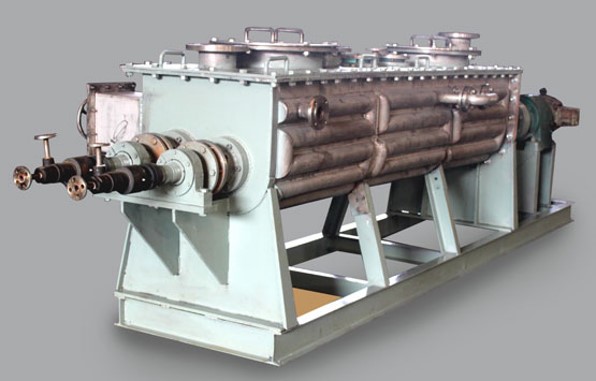

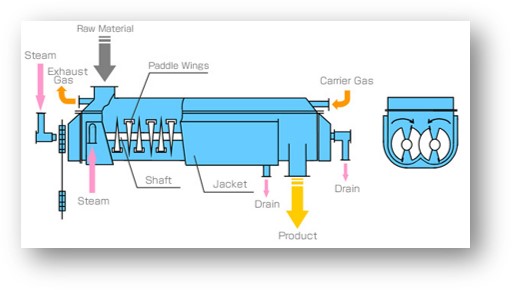

Paddle Dryers are used for drying of wet cakes, pastes and thick slurries like sludge.

The heating media like steam or hot oil flows through the hollow paddles as well as the jacket thus heating the paddles and the container walls.

The wet material gets dried after coming in contact with the paddles and container walls.

The design of the paddles is such that it is self-cleaning and does not allow the product to stick.

The product moves from one end to the other end and during this travel the moisture is removed.

Heating medium is usually steam or thermal fluid.

FEATURES

• It adopts conduction type of heat transfer; the heat transfer efficiency is high.

• The self-cleaning function of the heat transfer surface is good.

• The product quality is stable.

• The material loss is small, the product recovery rate is high.

• The material adaptability is broad, the product is dried evenly.

• It can combine drying and cooling together.

• The equipment with compact structure occupies small area.

• The design is unique, and maintenance of the equipment is easy.