MVR

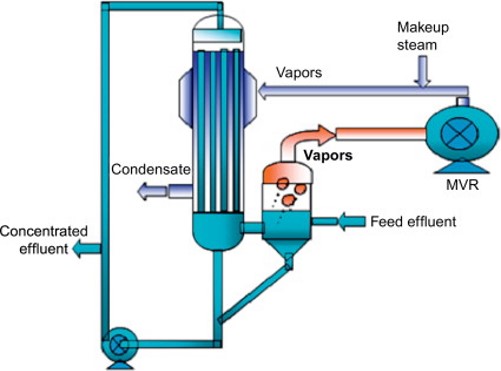

Mechanical vapor recompression (MVR) technology in evaporator plant consumes less energy as compared to conventional evaporator. Hence it reduces overall plant operating cost. In the conventional evaporator, most of the energy in the form of steam generated is either lost or partially utilized. In mechanical vapor recompression process, entire steam is compressed using mechanical pump at higher pressure which creates high heat energy to be used for further evaporation.

MVR (Mechanical Vapor Recompression) technology can reduce the energy consumption of the evaporation system significantly. The pressure, temperature and enthalpy of the secondary steam generated by evaporation increases after compressed by the steam compressor, then the steam enters the heating room as heat resource, to continuously circulate. This type of evaporation system consumes electrical energy for evaporation operations. Energy consumption of compression fan varies slightly, depending on different material properties.

ADVANTAGES

• No or few live steam required.

• Low energy consumption, low operation cost.

• Coupling with different types of crystallizers for continuous evaporation and crystallization.

• Compact design

• No condenser or one with small heat exchange area required.

APPLICATIONS

1. Food & beverage

2. Chemical

3. Pharmaceutical

4. Pesticide

5. Printing & dyeing

6. Metallurgy